-

제이크 밀러저희는 조립 라인의 중요한 VFD 교체를 위해 inverters-vfd.com을 선택했습니다. 제품은 완벽하게 일치했을 뿐만 아니라 이전 공급업체보다 더 저렴했습니다. 안정성 덕분에 잦은 트립 문제도 해결되었습니다. 뛰어난 가치와 산업용 부품의 믿을 수 있는 파트너입니다.

제이크 밀러저희는 조립 라인의 중요한 VFD 교체를 위해 inverters-vfd.com을 선택했습니다. 제품은 완벽하게 일치했을 뿐만 아니라 이전 공급업체보다 더 저렴했습니다. 안정성 덕분에 잦은 트립 문제도 해결되었습니다. 뛰어난 가치와 산업용 부품의 믿을 수 있는 파트너입니다. -

사라 첸inverters-vfd.com의 기술팀은 정말 큰 도움이 되었습니다. 서보 모터에 대한 저희의 응용 분야를 설명했더니, 뛰어난 동적 응답을 가진 모델을 추천해 주었습니다. 설치는 순조롭게 진행되었고, 정밀도가 사이클 시간을 단축시켰습니다. 전문적인 안내와 고성능 제품에 감사드립니다!

사라 첸inverters-vfd.com의 기술팀은 정말 큰 도움이 되었습니다. 서보 모터에 대한 저희의 응용 분야를 설명했더니, 뛰어난 동적 응답을 가진 모델을 추천해 주었습니다. 설치는 순조롭게 진행되었고, 정밀도가 사이클 시간을 단축시켰습니다. 전문적인 안내와 고성능 제품에 감사드립니다! -

데이비드 "빅 D" 코왈스키여러 PLC 유닛과 HMI에 대한 저희 주문이 정확하게 처리되었고 놀라운 속도로 배송되었습니다. 이를 통합한 이후, 저희 제어 시스템의 통신이 더욱 강력해졌습니다. 저희는 물류와 이러한 구성 요소의 견고한 성능에 깊은 인상을 받았습니다. 전반적으로 번거로움 없는 경험이었습니다.

데이비드 "빅 D" 코왈스키여러 PLC 유닛과 HMI에 대한 저희 주문이 정확하게 처리되었고 놀라운 속도로 배송되었습니다. 이를 통합한 이후, 저희 제어 시스템의 통신이 더욱 강력해졌습니다. 저희는 물류와 이러한 구성 요소의 견고한 성능에 깊은 인상을 받았습니다. 전반적으로 번거로움 없는 경험이었습니다. -

에밀리 화이트저희는 민감한 테스트 환경을 위해 저소음 스핀들 모터를 필요로 했습니다. 저희가 구매한 장치는 속삭이는 듯 조용하게 작동하며 일정한 토크를 유지합니다. 품질은 저희가 사용했던 일부 유명 브랜드 제품을 능가하며, 가격은 훨씬 저렴합니다. 특수 용도에 매우 적합합니다.

에밀리 화이트저희는 민감한 테스트 환경을 위해 저소음 스핀들 모터를 필요로 했습니다. 저희가 구매한 장치는 속삭이는 듯 조용하게 작동하며 일정한 토크를 유지합니다. 품질은 저희가 사용했던 일부 유명 브랜드 제품을 능가하며, 가격은 훨씬 저렴합니다. 특수 용도에 매우 적합합니다.

HV510 380-480V 3상 VFD (비동기/PMSM 모터용) 16세그먼트 PLC 다단 속도 운전 지원

| 원래 장소 | 중국 |

|---|---|

| 브랜드 이름 | COENG |

| 인증 | EC |

| 모델 번호 | HV510 |

| 문서 | HV510.xlsx |

| 최소 주문 수량 | 1 |

| 포장 세부 사항 | 통, 합판 상자 |

| 배달 시간 | 10-30 일 |

| 지불 조건 | L/C, T/T, Western Union |

| 공급 능력 | 20000/세트 |

무료샘플과 쿠폰을 위해 나와 연락하세요.

WhatsApp:0086 18588475571

위챗: 0086 18588475571

스카이프: sales10@aixton.com

만약 당신이 어떠한 관심도 가지면, 우리가 24 시간 온라인 도움말을 제공합니다.

x| 입력 전압 | 380V(-15%) - 480V(+10%), 3상 | 입력 전원 주파수 | (50Hz/60Hz)±5% |

|---|---|---|---|

| 입력 전압 불균형 | ≤3% | 출력 전압 | 0V 입력 전압 |

| 출력 주파수 | 0Hz-1500Hz | 보호 등급 | IP20 |

| 냉각 방법 | 공기 냉각 | 습기 | 15%~95%, 응고가 없습니다. |

| 강조하다 | 380-480V 3상 VFD 인버터,비동기 PMSM 모터용 VFD,16세그먼트 PLC 다단 속도 VFD |

||

가변 주파수 드라이브 벡터 인버터 기술 사양

|

기술 사양 |

||

|

힘 |

입력 전압 (uin) |

380V (-15%) -480V (+10%), 3 상 |

|

입력 전원 |

(50Hz/60Hz) ± 5% |

|

|

입력 전압 |

≤3% |

|

|

출력 전압 |

0V 입력 전압 |

|

|

출력 주파수 |

0Hz-1500Hz |

|

|

제어 |

모터 유형 |

비동기 모터/영구 자석 동기 모터 |

|

제어 모드 |

V/F, OLVC (오픈 루프 벡터 제어), CLVC (폐쇄 루프 벡터 제어) |

|

|

속도 범위 |

1:10 V/F; 1 : 100 OLVC; 1 : 1000 CLVC |

|

|

시작 토크 |

VF : 100% (0.5Hz); OLVC : 150% (0.5Hz); CLVC : 200% (0Hz) |

|

|

토크 정밀도 |

벡터 제어 모드에서 ≤ ± 5% |

|

|

토크 맥동 |

벡터 제어 모드에서 ≤ ± 5% |

|

|

속도 안정성 |

OLVC : 0.2%; CLVC : 0.1% |

|

|

토크 응답 |

벡터 제어 모드에서 ≤ 5ms |

|

|

가속/분리 |

0.0S 2 3200.0; 0.0 분 3200.0 분 |

|

|

토크 부스트 |

0.0%-30.0% |

|

|

과부하 용량 |

G- 모델 : 150% 1 분/5 분, 180% 3S/5 분 |

|

|

v/f 곡선 |

직선 유형, 멀티 포인트 유형, V/F 반 분리 모드, V/F 완전 분리 모드 |

|

|

입력 주파수 해상도 |

디지털 설정 : 0.01Hz; 아날로그 설정 : 0.01Hz |

|

|

기본 |

가속/감속 곡선 |

직선, s-curve |

|

간단한 PLC, 다중 속도 참조 |

제어 단자를 통해 지원되는 16 개의 속도 세그먼트 |

|

|

자동 전압 조절 (AVR) |

그리드 전압이 특정 범위 내에서 변하면 출력 전압을 자동으로 유지합니다. |

|

|

고정 길이 제어 |

고정 길이 제어 |

|

|

내장 PID |

폐 루프 제어 시스템을 쉽게 형성합니다 |

|

|

다중 운동 전환 |

2 세트의 모터 매개 변수를 사용하면 2 개 모터 간의 전환을 실현할 수 있습니다. |

|

|

가상 IO |

8 세트의 가상 DI/DO를 사용하면 간단한 논리 제어를 실현할 수 있습니다. |

|

|

과전압/오버 런트 스톨 컨트롤 |

과전류 및 과전압으로 인한 빈번한 여행을 방지하기 위해 작동 중에 전류 및 전압이 자동으로 제한 될 수 있습니다. |

|

|

정전 후 다시 시작하십시오 |

정전 후 다시 전원을 켜면 인버터가 자동으로 작동 할 수 있습니다. |

|

|

빠른 전류 제한 |

빈번한 과전류 결함을 피할 수 있습니다 |

|

|

입력 및 |

주파수 참조 모드 |

키패드, 터미널 업/다운, 다중 참조, 펄스 참조, 통신 |

|

아날로그 입력 단자 |

AI1, AI2 : 0V-10V/0 (4) MA-20MA |

|

|

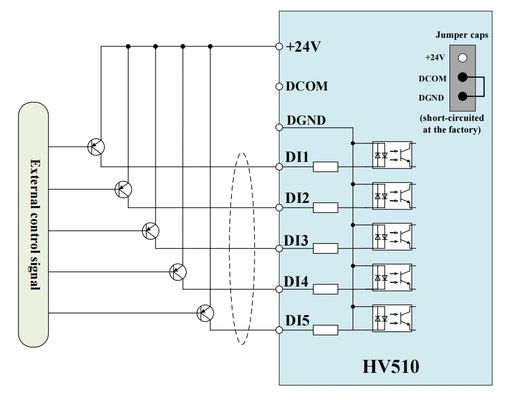

디지털 입력 터미널 |

DI1-DI5, 5 개 분리선 분리 기능이있는 5 개의 프로그래밍 가능한 디지털 입력 터미널. |

|

|

디지털 출력 단자 |

오픈-수집기 출력; 출력 전압 범위 : 0V-24V; 전류 부하 용량 : 50ma. |

|

|

아날로그 출력 단자 |

1 채널 0V-10V/0 (4) MA-20MA |

|

|

릴레이 출력 |

1 채널 형태 C 접촉, NO+NC |

|

|

해당 |

커뮤니케이션 프로토콜 |

MODBUS RTU (표준 구성); Profibus-DP, Canopen, Profinet IO, Modbus TCP/IP, EtherCat, Ethernet/IP (선택적 구성) |

|

용법 |

고도 |

≤1000m : 해소가 필요하지 않습니다. 1000-3000m : 100m 당 1% 감소로 전류가 증가하면서 증가했습니다 |

|

주변 온도 |

-25 ° C-+40 ℃ |

|

|

습기 |

15%-95%, 응축 없음 |

|

|

진동 |

3M3, IEC60721-3-3 |

|

|

저장 온도 |

-40 ° C-+70 ° C |

|

|

운영 장소 |

직사광선, 가연성 및 부식성 가스, 액체 및 전도성 입자 등의 실내. |

|

|

선택적 액세서리 |

인코더 카드, 커뮤니케이션 확장 카드, IO 확장 카드 |

|

|

보호 |

단락, 과전류, 오버로드, 과전압, 저전압, 위상 손실, 과도, 외부 결함 등으로부터 보호합니다. |

|

|

설치 방법 |

캐비닛에 설치되었습니다 |

|

|

보호 등급 |

IP20 |

|

|

냉각 방법 |

공기 냉각 |

|

![]()

![]()

![]()

전력 및 제어 정밀도

- 넓은 전압 호환성: 380V – 480V AC (± 15%/+10%) 3 상 입력을 지원하여 변동하는 그리드 조건에서 안정적인 작동을 보장합니다.

- 다중 운동 제어: 유연한 제어 모드 (V/F, 오픈/폐 루프 벡터)와 비동기 및 영구 자석 동기 모터와 호환됩니다.

- 높은 토크 성능: 달성0Hz에서 토크 시작 200%(폐 루프 모드), 매우 매끄러운 움직임을위한 ≤ ± 5% 토크 정밀/맥동.

- 빠른 동적 응답: ≤5ms (벡터 모드)의 토크 응답 및 가속/감속 조절 0.01 ~ 3200min.

고급 자동화 기능

- 내장 정보: PID 컨트롤, 16 단지 회의 프로그래밍 및 특징가상 I/O추가 하드웨어가없는 사용자 정의 로직 용 (8 구성 가능한 DI/DO 포인트).

- 항 회의 안정성: 자동 전압 조정 (AVR)은 그리드 불안정성 중 출력 일관성을 유지합니다.

- 스톨 예방: 스마트 오버 전압/과전류 억제는 성가신 트리핑을 최소화합니다.

강력한 연결 및 확장

-

다목적 I/O 옵션:

- 5 프로그래밍 가능한 디지털 입력 (DI5의 100kHz 고속 펄스).

- 2 아날로그 입력 (0–10V/4–20MA), 1 아날로그 출력, 릴레이 출력 (NO+NC).

- 고속 펄스 출력 (DO1을 통한 100kHz).

- 다중 보호 콜 통신: 표준 MODBUS RTU + 옵션 PROFIBUS, CANOPEN, ETHERCAT, ETHERNET/IP 등을위한 원활한 PLC/시스템 통합.

산업 탄력성

- 광범위한 환경 관용: -25 ° C ~ +55 ° C (Derated) 및 ≤3000m 고도에서 작동하며 15-95%의 비 응축 습도로 작동합니다.

- 포괄적 인 보호: 단락, 위상 손실, 과전압/전류 및 과열로부터 보호합니다.

- IP20 등급 및 공기 냉각: 실내 산업 환경에서 캐비닛 설치를 위해 설계되었습니다.

확장 가능한 기능

-

선택 모듈:

- 정밀 피드백을위한 인코더 카드.

- 그리드 동기화 전압 감지.

- 통신 어댑터 (USB, Profibus, Canopen).

- 원격 키보드 작동.

에너지 효율 및 안전

- 최적화 된 과부하 처리: G- 모델은 150% 하중 (1 분) 및 180% (3s)를 유지합니다. P- 모델은 110% (1 분)에서 효율을 우선시합니다.

- 자동 복구: 수동 개입없이 전력 후 실패를 다시 시작합니다.